![MC - Our Cashmere Banner sample[(000001)2019-09-17-19-44-12]_1.JPG](https://images.squarespace-cdn.com/content/v1/5aaae370f7939232bba75ac0/1568767546505-FHNQIW738VLKOZ06LG6L/MC+-+Our+Cashmere+Banner+sample%5B%28000001%292019-09-17-19-44-12%5D_1.JPG)

Basic Cashmere Knowledge

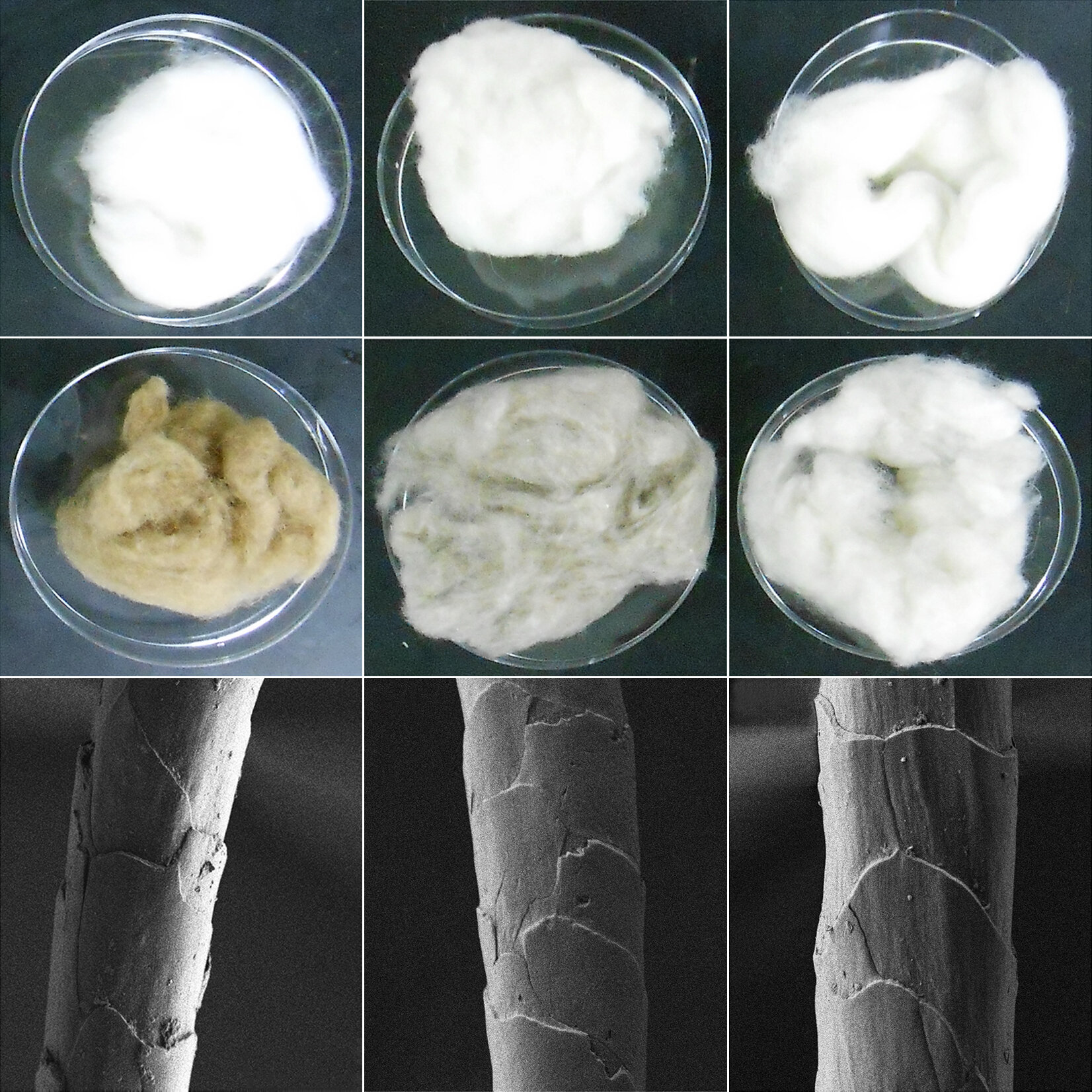

What is organic cashmere? Organic Cashmere is simple and clean. Pure unbleached, untreated fibers, and harvested through combing process. Cashmere fiber specifications are 13-17 microns and 34-42mm long.

Where does cashmere come from? The cashmere raw material is originated in Hohhot, Ordos, Baotou and Ulanqab area, part of Inner Mongolia Province; from goats like Arbas, Alasan and Erlangshan. Arbas breeds are considered high-class for its undercoat.

What color is cashmere? There are only 4 naturally occurring cashmere goat hair colors: Light Cream, Light Grey, Beige and Brown. The light color fibers are the rarest and softest ones, they will never be dyed. The beige fibers will be naturally dyed to make light shade colors while brown fibers will be used for dark shade colors.

Sustainability & Environmental Response

At Mongolia Cashmere Manufacturers, we are fully aware of the increasing carbon footprints on our planet and how these affect our environment, which is why throughout the production process we have a true commitment to environmental protection and sustainability.

We are dedicated to using responsibly sourced raw materials and we care for the well-being of all animals used in the production of our cashmere yarns. The ethical practices toward animal welfare go hand in hand with our values when considering grassland conservation initiatives. We work with the local herders to manage the number of animals per acre to prevent overgrazing and desertification. We need to protect the health of grasslands as the livelihoods of the herders and animals depend on healthy soil for their food source. Sustainability begins at the source, which is why traceability is key to bringing transparency and aligning our partners to pursue sustainable practices at every level of the supply chain. We are proud to implement the latest available technologies from raw materials to treatment-dyeing practices and wastewater management to ensure everything we create does not affect any form of life

We are conscious and we are constantly trying to find methods on how to efficiently reduce our impact on environment.

Sourcing Ethics

Once a year our team is visiting local herders to curate the best cashmere raw materials. We primarily focus on herders' ethical approach, standards of raising the goats, and husbandry best practices. We are always handpicking the raw material strictly from goats that are only combed. The goats naturally shed their undercoat and when the days lengthen, you have to catch the right period and comb the down out. It’s similar to combing a dog who is shedding its winter coat during the springtime. If herders don’t comb the cashmere, it will simply fall on the ground.

It is a very gentle process and there is no harm involved during the process of combing; in fact, veterinarians are stating that it is beneficial for the goats.

We do not accept or use any fibers that are obtained by live-plucking or skinning, and no animals are slaughtered specifically for the production of any of our products. Our fibers are responsibly harvested only by natural shedding or clipping. We source all our products with integrity, to uphold the highest quality of our products, and to honor our ethical standing, with genuine respect for social responsibility, sustainability, and the environment.

Cashmere DNA

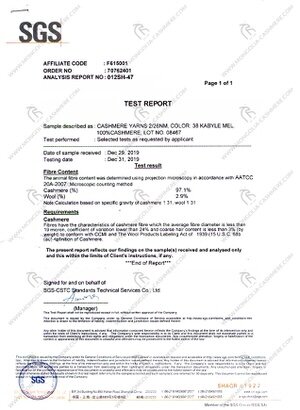

Cashmere is one of the finest and softest animal fibers used by textile industry. False declaration is quite common due to its scarcity and high economic value. We have developed an objective method for quantifying cashmere and wool mixture based on DNA technology. Mitochondrial DNA, a species-specific genetic material exists in each cell, presenting a relatively strong capacity to resist physical and chemical treatments, seems to be an ideal target for species identification.

Our cashmere is traceable from a specific region right through to the individual cone and therefore to the garment. Documentation from fiber collection through computerized inventory control ensures transparency of information.

We always test every batch of raw cashmere fibers for purity at our independent laboratory to check on a DNA molecular level for 100% cashmere and its origins, so that you can rest assured that our cashmere is real, wholesome and pure.

Because of testings we have the advantage to be in control of everything starting from the raw materials ending with the finished garments.

The Art of Eco-Dyeing

Enhanced environmental awareness has motivated scientists to come up with more ecological methods of dyeing, such as low-impact dyes and natural colorants. Low-impact dyes do not contain heavy metals, toxic substances, are energy-saving, uses less water, salt, and processing materials overall. It is also more readily recyclable, and there is no need for discharge and drain processes that waste large amounts of water. Even the wastewater can be reused as the whole process occurs at a neutral pH level of ~7.0, meaning no acids or alkaline need to be added to the water used. During cashmere dyeing process 70% of the water used at our partners’ dye houses are recycled back (Closed Loop Water Filtration System) into the production through a high powered wastewater treatment plant. All chemicals used must meet strict toxicity and biodegradability criteria.

Natural colorants refer to pigments that exist organically and come from sources found in nature such as plants, animals, fruits, insects, and minerals without the involvement of any chemicals in the process. Therefore, natural colorants are among candidates for developing green textile dyeing process and serving as better alternatives or co-partners to toxic synthetic dyes.

The practice of hank dyeing techniques makes our cashmere superior. Dyeing cashmere fibers on a very low-temperature shows superlative advantages. We prefer this method because there are no spikes in high and low temperatures. We have noticed to have more control over the color pigmentation, and the fabric feels softer and stronger. However, the only downside of the hank dyeing technique is extra processing time, which means we need to prepare in much advance.

Our yarns are dyed, spun, and engineered with the environment in mind, ensuring there are no harmful chemicals used in the production process and being conscientious that pollution is not leaked into the water or air.

It's our priority to understand your business, where you are and where you're heading, so that the solutions we offer are just right for you.

FEI LIU | GENERAL MANAGER

The Pursuit of Creating a Cashmere Legacy

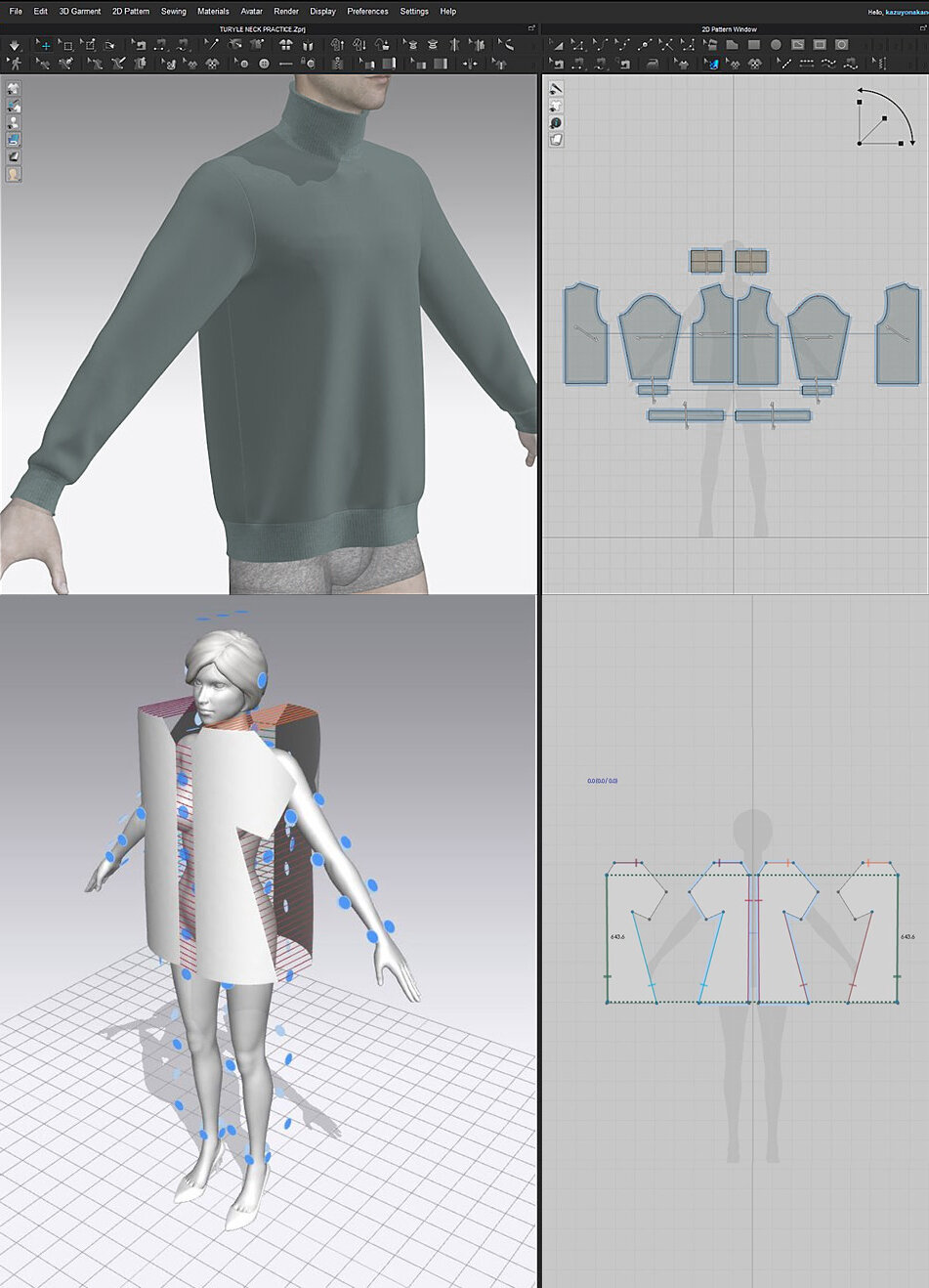

Due to uprising competition, we are regularly planning and acting on improving our company’s assets to stay relevant on the market for as long as possible. As a company driven by passion, analytical skills, and aiming for big goals, it is inevitable to oversee the trending of fashion being merged with science and technology.

With the fast development of technologies, integration of the industry chain is becoming a key point for enterprises around the world. The direction of the future knitwear industry will see a close collaboration between the whole chain cells, such as fiber suppliers, spinners, trend forecasters, swatch-houses, machine-makers, knitters, and retailers. The partnership between spinners, knitters, and machine-makers will lay a solid foundation for the fashion industry. Machine-makers are also following trends and developments of the fashion industry, thus optimizing the appeal of their machines.

Mongolia Cashmere Manufacturer is heavily invested in modern equipment, virtual software and futuristic resources. For example, we work with CLO3D, Marvelous Designer and SDS®-ONE APEX3 system from SHIMA SEIKI. With these programs we can easily process Tech Packs Data in a true-to-life 3D Virtual Design Garment Simulation, it can render visual swatches in different patterns and colors without actually making them.

Our next step is to firmly keep an eye on 3D Fashion Design - Virtual Reality Software with Machine Learning Capabilities because that is where fashion’s vectors are now pointed to.

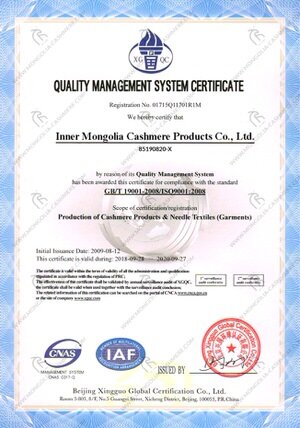

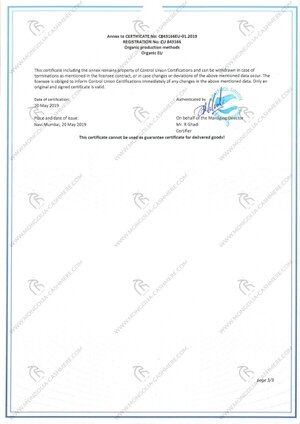

Certifications

Since we are working with luxurious natural fibers, we need to ensure that each piece of material will be transformed into a long-lasting and sustainably ethical product.

We can achieve these results only by using fibers that are conforming with the universal standard of quality.

We and our spinning partners are closely working together on developing innovative methods for achieving the quality that is tested, enforced and backed by such independent leading textile institutes like OEKO-TEX, Control Union, and SFA.